For window manufacturers the replacement market is huge but the problem with replacement windows is that the sizes are not standardized. So a window manufacture has a hard time creating tooling to fill some of these sizes that might not have warranted full production tooling. That was then. This is now.

Extremely large Cut Sheet Tooling for Window Manufacturer

Outside The Box

The goal of this unique program was to be able to produce flexible mold that would form specialty frame covers from .041” PVC sheet for windows in .125” size increments that are typically run in low lot sizes. Omnitool’s task was to design and build the tooling that would be integrated within a brand new custom Modern shuttle former.

Built for Flexibility

This tooling had lots of “extras” added to it for quick change-over times. In the first year alone they did over 20,000 changeovers.

Size Does Not Matter

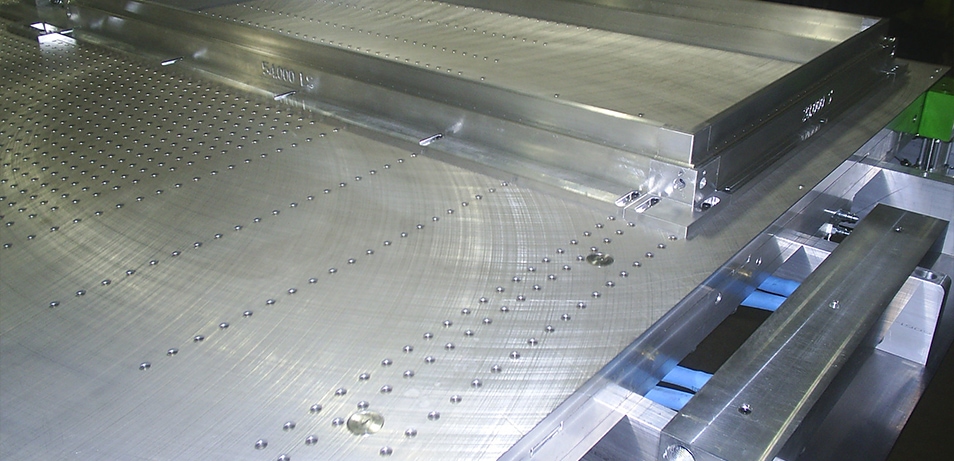

The scale of this tool is amazing. The cooling plate size was 68” x 92” and the stick-mount plate had over 2300 (¼-20) holes. The Mold required a temperature controller as well as an Ethernet connection.

For more information on this design and manufacturing project, please see the details below.

For details about our other services please contact Omnitool

info@omnitool.com 763.535.4240

Cut Sheet

| Tool Type | "Custom" Flexible Quick Change-over Tooling |

|---|---|

| Tool Dimensions | 70" X 106" X 12" |

| Shrinkage | .003" |

| Product Size | 17" X 24" Up To 60" X 84" (.125" increments) |

| Material Formed | .041 PVC |

| Design Software Used | Pro Engineer |

| Shuttle Former | Modern Machinery Model 7296SS Three Station (oven, form & load) |

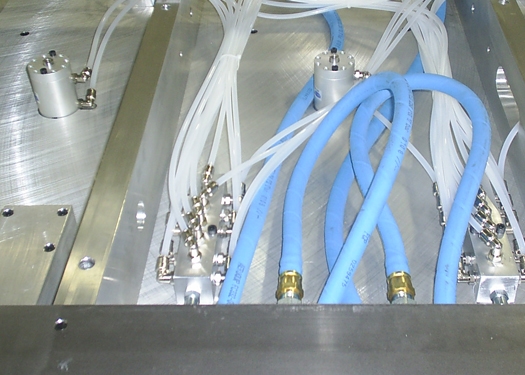

| Master Cooling Base | Water Cooled automated lock down & positioning |

| Vacuum Plate | Equal Distibution |

| Sub-plate (Removable) | Inserted, Tool Less Vacuum Ports, Self Locating & lock Down |

| Mold Sticks (Male) | Contact Cooled |

| Qty 162 | Top Mounted Self Aligning |

| Mold Corners (Male) | Contact Cooled |

| Qty 8 | Top Mounted Self Aligning |

| Hook ups | Vacuum: 1-1/2" (Thru Platen) Qty 2 Cooling: 3/4 npt Qty 2 "IN" 2 "OUT" |