When a major manufacturer approached Omnitool to design and build a full suite of tooling to create a side vented berry package comprised of a form tool, a pre-punch station and a perimeter trim station we knew we could draw upon or 70+ plus years of combined experience to provide a solution that could stand the test of time. The challenge of building full tooling solutions is multifaceted and we pride ourselves on building the best full service tooling solutions in the industry.

Form Tool, Pre-Punch and Perimeter Trim Tooling for Berry Container

Experience Matters

Designing these systems requires a full knowledge of the issues associated with installation and running this type of tooling. Omnitool’s engineering department will travel to a site to ensure that we fully understand the requirements.

Performance Evaluation

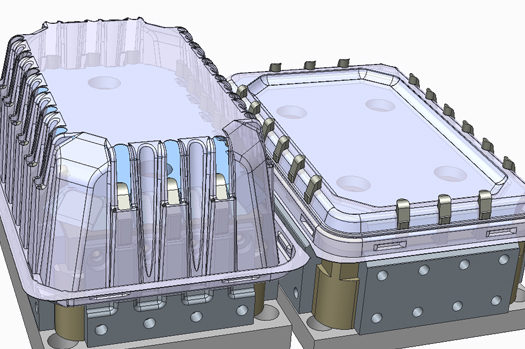

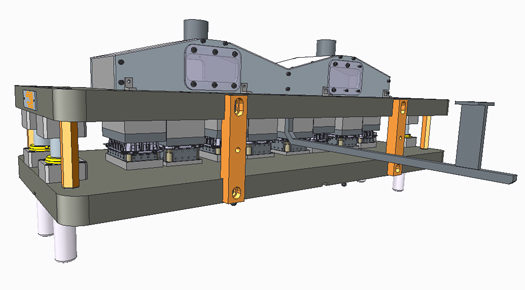

Solid models are invaluable for detecting potential issues and for communicating design intent. This solid model assembly is used as a platform for a formal tool review prior to cutting metal.

Integrated Process

Form, punch and trim, we manage the entire program with input from your engineering and processing departments

World Class Solutions

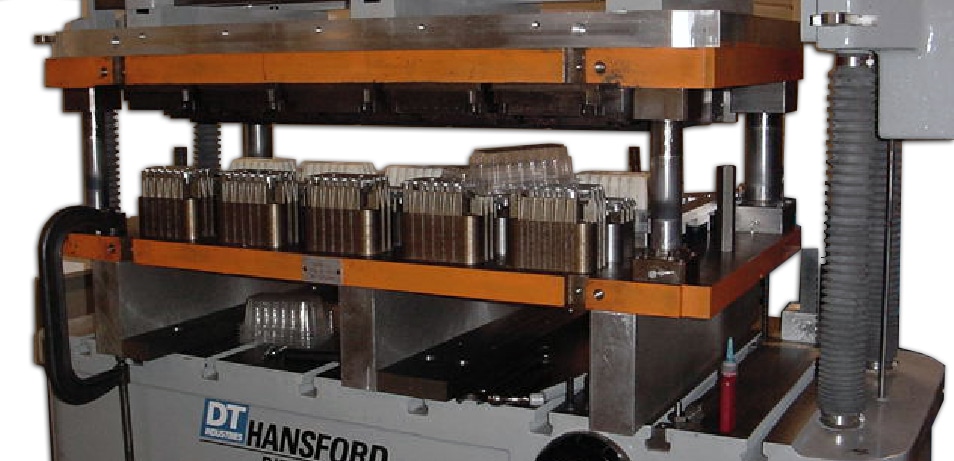

The in house capabilities at Omnitool are perfectly suited to handle challenges of this nature. The pre-punches need to be held on location rigidly and they need to be easily serviceable. Each tool is rigorously tested prior to shipping.

For more information on this design and manufacturing project, please see the details below.

For details about our other services please contact Omnitool

info@omnitool.com 763.535.4240

TRIM TOOL/PERIMETER

| Project Name | Berry Container |

|---|---|

| project scope | Narrative |

| Market served | Food Packaging |

| Material Trimmed | .018 PETE |

| Number Across | 4 |

| Product Size | 2.25 X 7.50 9.87 |

| Mounting | Lyle 150 |

Die Set Spec

| Posts | 4- 2" posts |

|---|---|

| Shut Height | 10 |

| Open Height | 20.5 |

Die Spec

| d-2 individual dies 48-52rc .0001/.0003 clearance total |

|---|

Punch Spec

| Type | Blanking |

|---|---|

| Material | d-2 Blades a-2 holder |

| Hardness | 60-62rc |

| Engagement Depth | .250" @ 10.000" |

| prepunch stripper | nylon stripper spring actuated |

| Delivery Time | 2 Weeks Design 8 Weeks Build |