We design and build precision thermoform prototype tooling. Starting with prototype tooling can help you assess any necessary product or tooling modifications before committing to designing and building production tooling.

Prototype Tooling

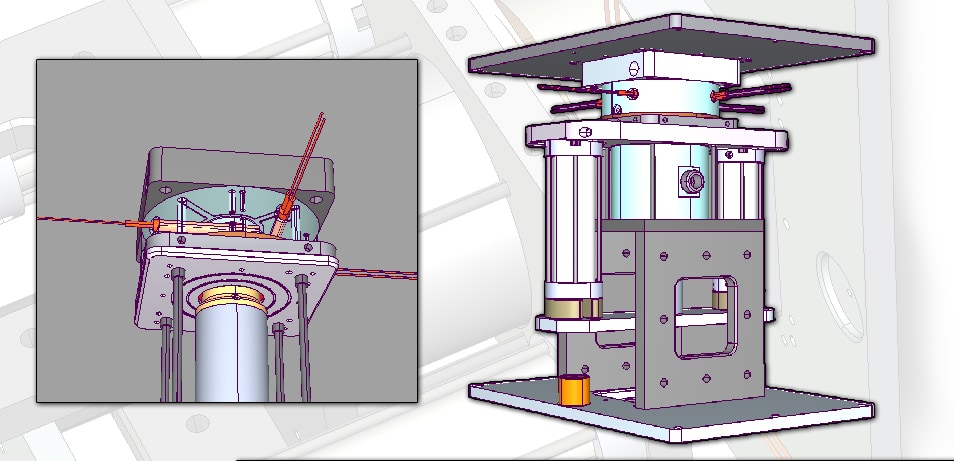

Prototype Thermoform Tooling

We can build prototype tooling from customer drawings or create a unique design based on customer requirements. We put our experience to work to properly evaluate each prototype project for design optimization and manufacturability. We move quickly to design and build prototype tooling with delivery times as short as 1-2 weeks. Our prototype cavities can also be installed in existing production tools with the same trim to test real world performance.

Rapid Prototype Thermoform Tooling

We design and manufacture rapid 3d printed thermoform tooling so you can get part samples in days after design approval.

Product Sampling

Sample parts can be invaluable for testing a product’s merit and manufacturability prior to investing in a machined prototype cavity and as a visual aid for supporting your selling efforts with prospects/customers. We can form parts from rapid tooling, prototype tooling or production cavities. We provide sampling runs as small as 12 or as many as you need. We can mold samples using most resins in solid sheet as well as foam.

For more information on this design and manufacturing project, please see the details below.

For details about our other services please contact Omnitool

info@omnitool.com 763.535.4240

Prototype Thermoform Tooling Capabilities:

| General Capabilities |

| ||

| Process |

| ||

| Mold Material | Aluminum | ||

| Material Run Thickness | .015 to .035 in up to .080 in | ||

| Thermoform Material | PP, PS, HIPS, OPS, PVC, APET, PET, ABS, HDPE, EPS, PC, RPET, TFPP | ||

| Tooling Components |

| ||

| Trimming | Steel Rule Die Hand trimmed | ||

| Machining | 5 axis High Speed Machining Centers Milling, turning, wire EDM | ||

| Testing |

| ||

| Production Volume | Design verification 1-50 Short Run Production 1-200 | ||

| Typical Lead Times Available | 1 to 2 weeks | ||

| Tolerance (+/-) | .002 to .005 in | ||

| File Formats | All file formats accepted | ||

| Industry Memberships | Minnesota Precision Manufacturing Association Society of Plastics Engineers |