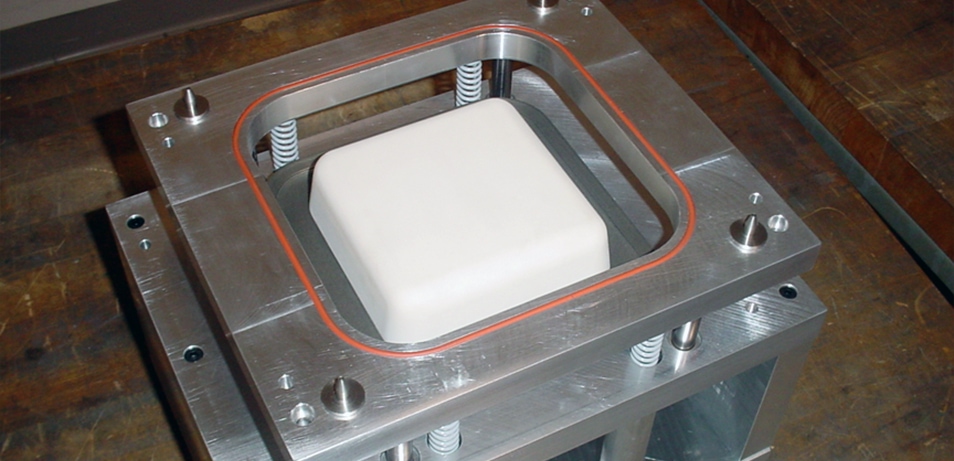

A customer from the packaging industry approached Omnitool to design and manufacture Prototype tooling for a meat packaging prototype prior to investing in production tooling. A prototype of this nature is used to test the market reaction and to test performance through the automation systems. We typically create prototypes of this nature in two weeks.

Design & Manufacturing of Prototype Tooling for the Packaging Industry

Proto-Typical

The product surfaces were built from a customer supplied 2d data using advanced surfacing tools by our skilled designers. Then it was incorporated into an previous tooling base located in our customer’s prototype lab. Photo realistic renderings were produced to secure our customer’s approval prior to cutting aluminum.

Quick Turn

The cavities were contact cooled and coated with Teflon. The tool also had a spring loaded ejector plate due to the undercuts in the stack lugs.

Small But Powerful

The prototool was designed to work within our customer’s prototype former where they can quickly change out tooling. The tool had a clamp plate driven off of pneumatic cylinders and the plug was cut from syntactic foam to minimize heat transfer.

For more information on this design and manufacturing project, please see the details below.

For details about our other services please contact Omnitool

info@omnitool.com 763.535.4240

Proto-tooling

| Tool Type | 1 up Prototool |

|---|---|

| Tool Dimensions | 9.75 X 11 x 14 |

| Shrinkage | .02" |

| Product Size | 6.75 x 6.75 x 2 |

| Material Formed | .015 P |

| Design Software Used | Pro Engineer / Cadkey |

| Mounting | Lyle Lab Former |

| Cavities | 6061-t6 Contact Cooled Graphic Inserts .02 Vac Hole Teflon Coated |

| Plug Assist | Syntactic Foam |

| Stripper | Perimeter Clamp Air Actuated |

| Clamping | Spring Activated Perimeter Clamp |

| Coining Ring | 6061-t6 Teflon Coated |

| TRIM | SRD |

| Delivery Time | 2 Weeks |