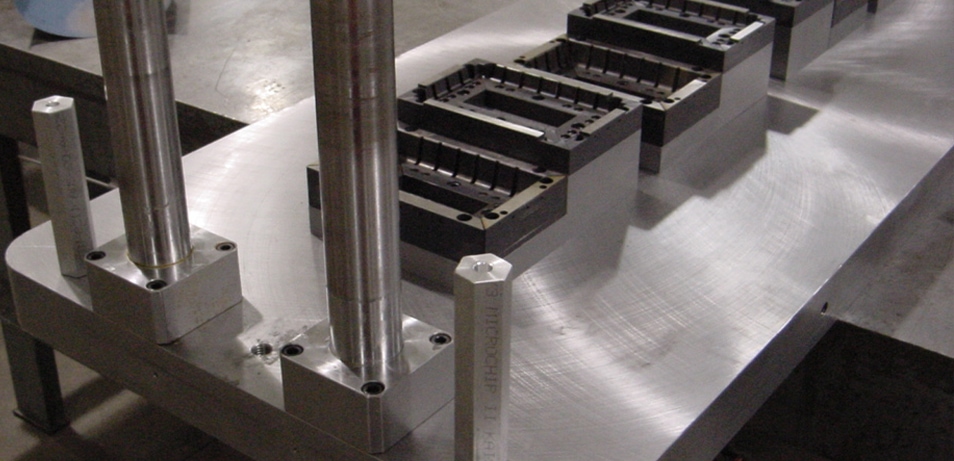

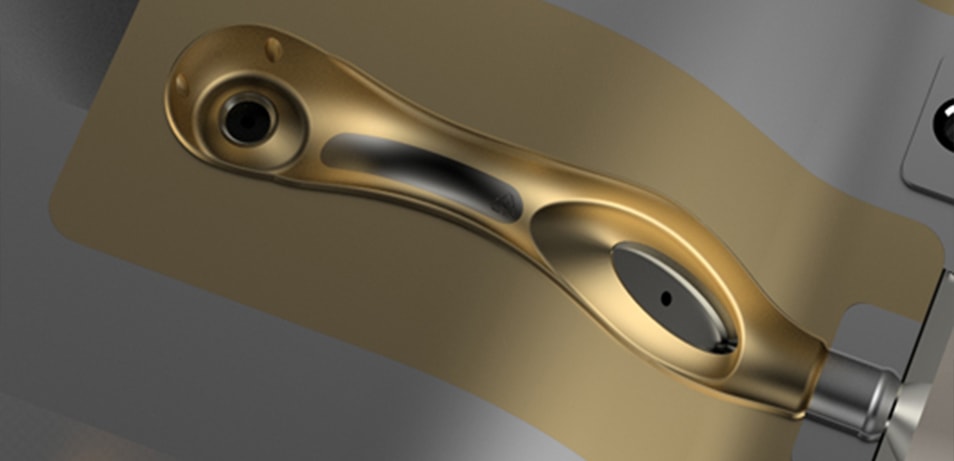

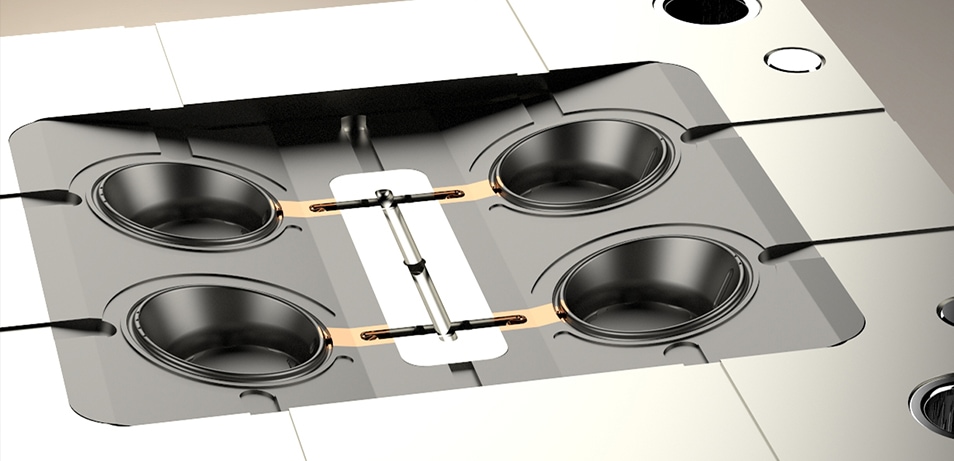

Omnitool designs and manufactures world class thermoform tooling, match metal trim dies and Pre-punch tooling as well as blow mold and injection mold tooling. Whether we start from a napkin sketch, a product sample or CAD data, our Engineering Department will work with your requirements to ensure your tooling is delivered on time and on budget. That includes a mid-program review and a final tool review.

All of our tools are tested to ensure we deliver on our promises and we have invested in the equipment to do so. We employ coordinate measuring machines, die handlers and heater controllers to ensure that our tooling works as intended, the first time. We have been designing and building tooling for over 35 year and know that It’s a major investment and we work hard to maximize your return.

For high-quality tooling design and manufacturing services delivered on time and at competitive prices, contact us today 763.535.4240 info@omnitool.com