At Omnitool we know that the tools are run hard, some of them are even hung up wet. We provide thermoform tooling repair and maintenance services ranging from re-sharpening trim dies and repairing cavities to line-swap tool adjustments and material change over modifications; all of which help extend the life, or increase the value, of our customers’ existing tooling.

Tooling Repair & Maintenance

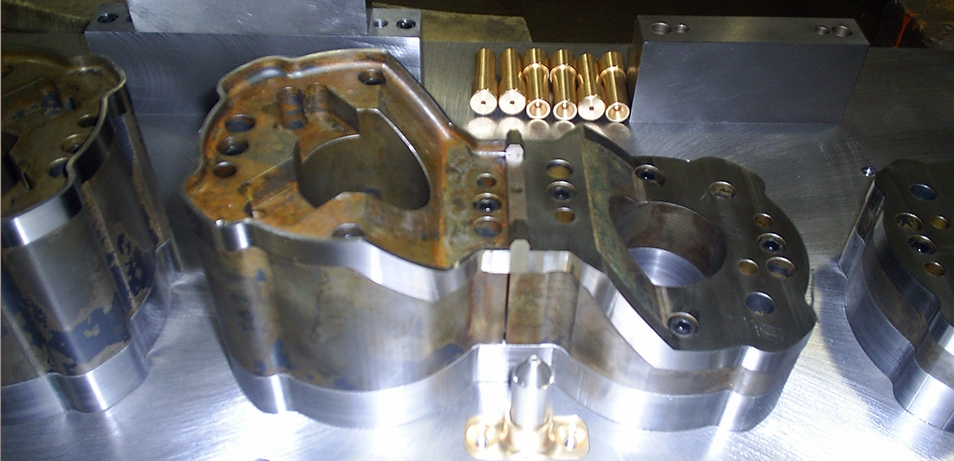

Tool Refurbishment

Omnitool’s skilled technicians can rebuild older tooling to better meet client requirements. If necessary, we will design and manufacture new tooling components to fulfill any desired improvement.

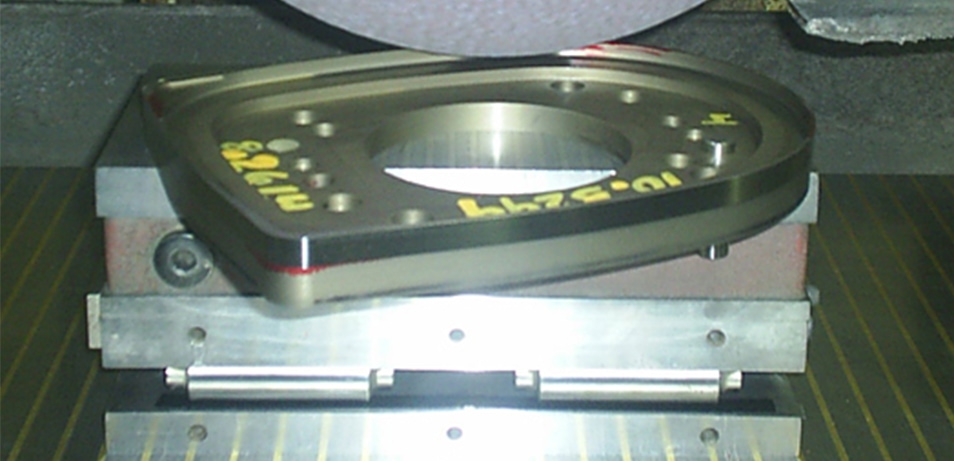

Punch and Die Sharpening

Drop a wrench into your trim press? We are here to help. We offer expedited time lines to get you back in business.

Tooling Maintenance

We provide preventative maintenance, in a fast, high-quality operation that saves our clients time and money over complete tool replacement.

Tooling Repair

Screwed? We dont judge, we just fix it get it back to you so you can keep hammering.

Tooling Repair & Maintenance Capabilities

| General Capabilities |

| ||

|---|---|---|---|

| Services |

| ||

| Materials | Aluminum, Steel, Wood, Syntactic Foam | ||

| Testing |

| ||

| Typical Lead Times Available | Case by case basis Sensitive to their production need | ||

| Quality Control | Use data from the production thermoform tooling | ||

| File Formats |

| ||

| Industry Memberships | Minnesota Precision Manufacturing Association |